THE SME TEAM IS CURRENTLY TRAVELLING IN INDIA

Hover to zoom

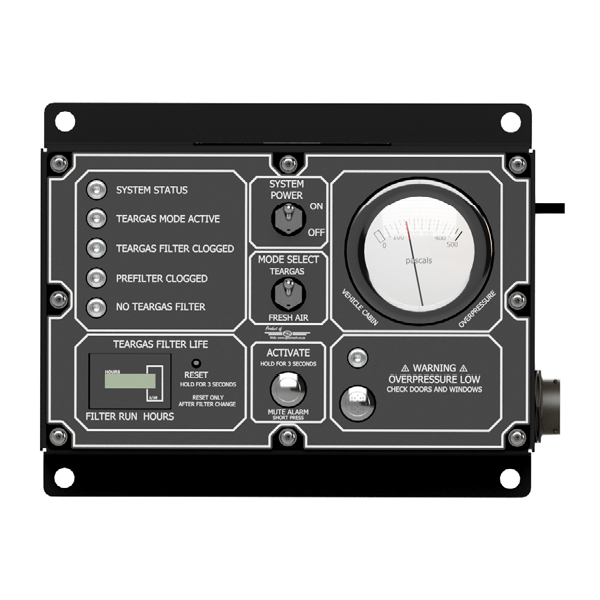

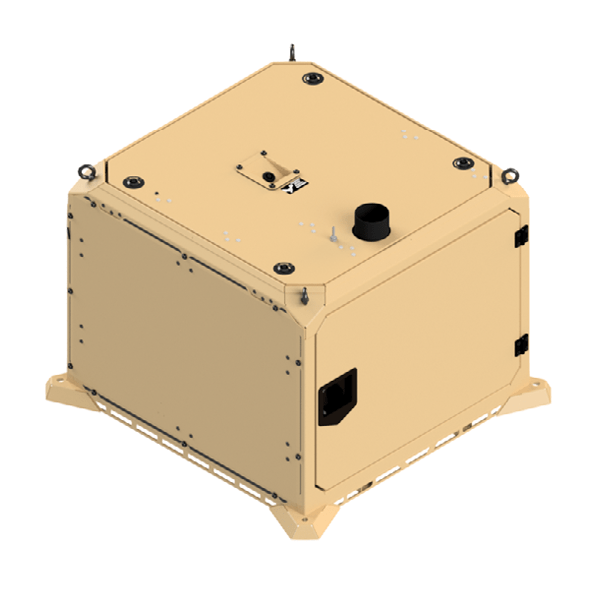

Teargas Filter Unit - Internal Mounted

Internal Mounted

Ref no. CBRN-I-01

|

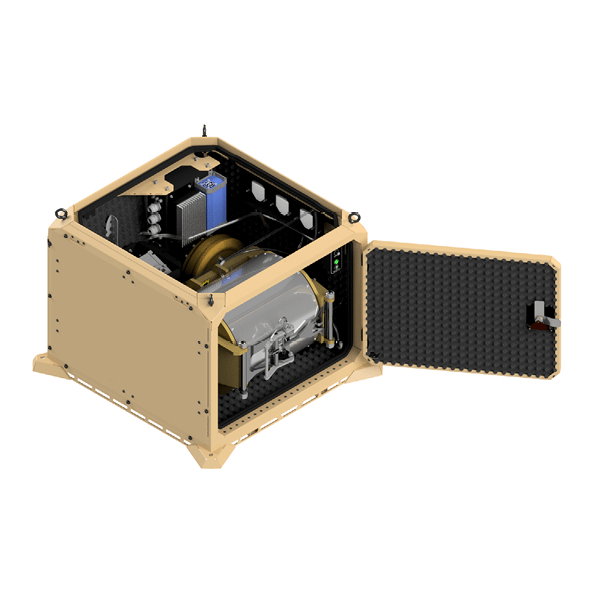

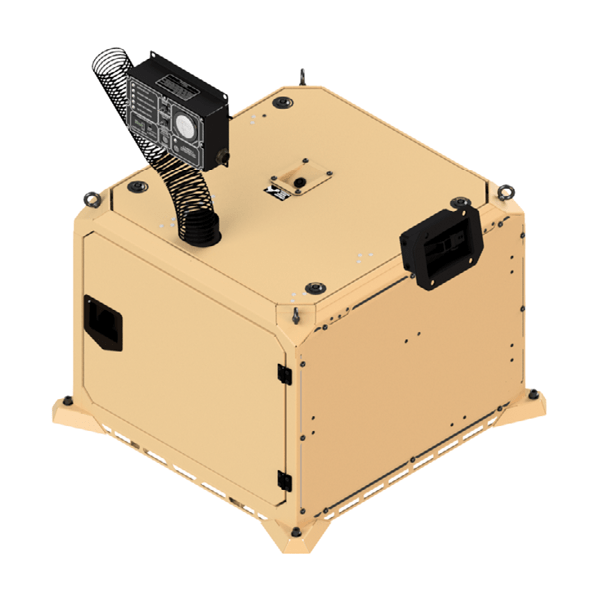

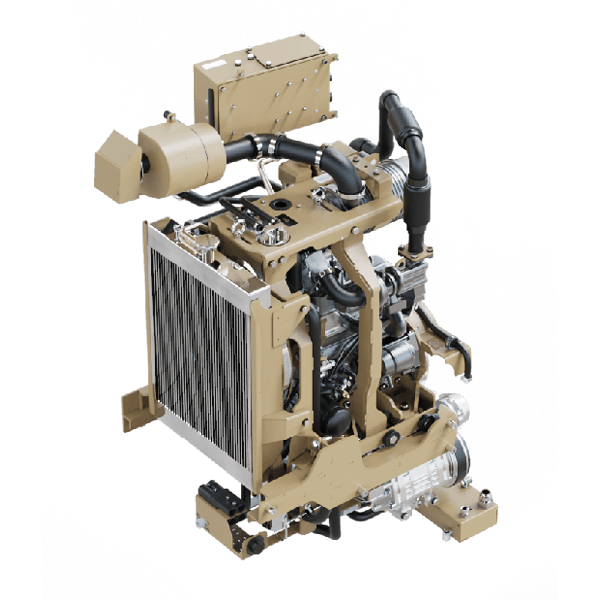

The Teargas Filtration Unit solution removes teargas agents from the fresh air entering the vehicle to ensure the crew is always breathing safe and clean air. The filtration systems operate under positive pressure, maintaining a “safe cell“, and ensuring all hazardous gasses are not able to enter the vehicle or cabin. Cyclone and pleated filters are used to clean the air and remove the majority of dust particles whereafter a motorised valve directs the air to the personnel cabin either directly (no threat), or via the CBRN filter (threat detected). The solution provides motorised valve switching, along with a manual override. If hazardous gas is detected and the operator is aware of a threat, the operator can press a button on the HMI Controller for the 3-way valve to automatically switch from Fresh air to Teargas-mode. This will direct the contaminated air across a special Teargas filter for the removal of the teargas agents before the air enters the vehicle. At the same time, it will increase cabin pressure and will operate at less than 90dB ensuring crew comfort is within acceptable noise levels. Optionally, SME can provide adaption to include integration into existing air conditioning systems (heating and cooling) as well as providing UV-C Filtration solutions for additional protection. Sufficient sealing of the vehicle or container is the responsibility of the manufacturer thereof. The Teargas system is a bolt-on integrated unit and requires the container or vehicle to be sealed sufficiently to reach an overpressure of at least 200-800 Pa. |

Specifications

|

Teargas Protection |

STANAG 4632 (AEP-54) |

|

Power Supply |

28VDC, 30A |

|

Modes |

Fresh Air & Teargas – (motorised switch with manual override) |

|

Max Airflow |

170m3/h |

|

System Type |

Overpressure System |

|

Overpressure |

Pressure regulation between 200-500Pa |

|

Teargas Filter |

Ø 325mm x 369mm H |

|

Filtration |

95% Efficient Particle Cyclone Filtration; Primary Pleated Filter, HEPA with Teargas Filtration Cartridge |

|

HMI |

Stand Alone - hardwired LED fault and/or warning indication & alarm |

|

Fault Finding |

Bluetooth |

|

Enclosure Protection |

IP54 |

|

System Weight |

150kg excluding armour protection |

|

Optional |

|

|

Motorised 3-Way Valve Switching |

Motorised 3-way valve switching when activating the Teargas system from the default Fresh Air Filtration to Teargas filtration. |

|

Network |

CAN Bus for integration to vehicle diagnostics |

|

Armour Protection |

To client specification |

Application